Pressure switches encounter many various fluids and gases including air, water, oils, cleaning fluids, coolant, etc. There are applications where the pressure switches come in contact with gases and fluids and need to be free of any oils. Oils are used in the pressure switch setting process and the residual can contaminate a customer’ fluid and gas system.

To counteract this potential contamination, Gems offers an option to clean the pressure switches to be “Oil-Free” (OF). When selected as an option, Gems will handle the pressure switch differently during production:

- Parts are pre-cleaned before they are assembled to ensure no cutting fluids & debris are present.

- The switch will be assembled.

- The switch will be set to the appropriate pressure set point.

- Then, the completed device will be tested for correct operation.

- Finally, place the pressure switch into a sealed plastic bag to maintain it’s Oil-Free state.

Applications for Oil-Free Pressure Switches:

- Medical Gases: oxygen, nitrogen, carbon dioxide, nitrous oxide, etc. needs to be oil-free for they can be ingested into the human body

- Hydraulic oil: foreign oil contaminations can harm delicate equipment

- Water monitoring: no oil should be in the system

Notes:

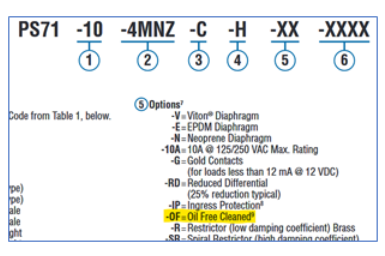

- Not all pressure switches offer the Oil Free (-OF) cleaning option. If it does, it will be on the data sheet here:

- Note 9: The Oil Free Cleaning option requires a Stainless-Steel Housing (pressure fitting). The Oil Free options is not available with brass and 12L14 Zinc-Plated steel housings.

Industries:

Adjacent Products:

- 1100 Series Pressure Sensors (pressure monitoring)

- LS-350 Level Switch with Siphon Tube (fluid containers)

- Valves (Ventilators)

- FS-500 Flow Switch and RFO Electronic Flow Sensor (medical lasers, tattoo removal)

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER