Gems Sensors manufactures solenoid valves and when using any product, it’s good practice to understand common failure modes and how to limit or prevent them from happening, and how to diagnose them.

Failure modes will depend on the type of valve configuration selected, so we’ll start with the most common, 2-Way Normally Closed (2-Way NC).

Understanding the Valve’s Operating Principles:

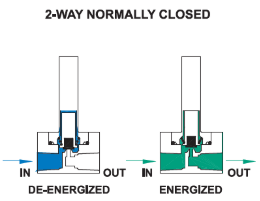

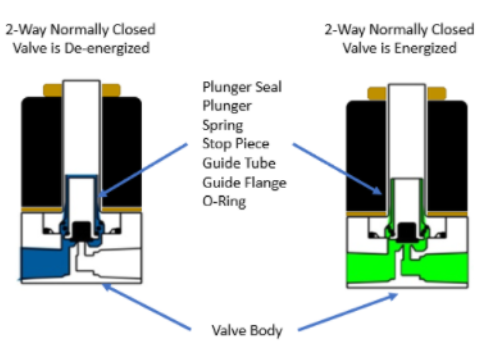

To properly diagnose the problem, its crucial to understand how the valve operates. On a 2-Way NC valve, when no power is applied to the valve (deenergized) the valve is closed. In this state, a spring holds the plunger down onto the seat, and thus the seal at the bottom of the plunger creates the liquid and airtight seal. When power is applied to the valve (energized) the valve is open. In this state, the coil overcomes the spring force and creates a magnetic field that pulls the plunger up and allows flow through the valve. Knowing the basic operating principle is key to being able to diagnose and remedy a failure. Review the flow schematic for more information. Review the components that make up a solenoid valve here.

Since a valve can be open or closed, we can break the failure modes down to those two categories, valve won’t open, or valve won’t close.

2-Way NC Valve Won’t Open:

Inlet pressure or overall, Max Operating Pressure Differential (MOPD) is greater than valves rated MOPD. As mentioned above, the spring force is holding the plunger down, and the coil will have to overcome this force. It also must overcome the force of the inlet pressure as it is over-seat, pushing the plunger down. Therefore, if the inlet pressure is above the valves rated MOPD, it will not open. Review more about MOPD here.

Coil not receiving voltage or incorrect voltage: This failure mode may not have anything to do with the valve itself, but instead with the voltage supplied to it. Each coil is designed to accept a certain voltage to provide enough power and magnetic force to pull the plunger up. If the coil is provided with a lower voltage or no voltage at all due to an issue with the circuit, the valve will not open. There is a + / - tolerance of 15% the coils rated voltage but when it falls out of the range the valve will not operate correctly. If you would like to use a Pulse Width Modulation (PWM) review more about that here.

Coil not providing magnetic force: If after checking for proper voltage being applied to the coil; the issue may be with a shorted or burnt out coil. You can check the resistance of the coil to make sure there is some resistance. If you receive an open or infinite resistance reading, then the coil has failed and needs to be replaced.

If the coil has failed, it’s also important to understand why the coil may have failed to prevent or limit it from happening again. If the valve is in a high moisture area, moisture may have wicked into the coil and caused a short. Sloping electrical conduits away from the coil will help moisture drain away. Also, encapsulated, and molded coils will provide a higher resistance to moisture intrusion then a tape-wrapped coil. Learn more about selecting the correct coil housing here.

Another potential failure mode is if the media can cause the plunger seal to swell and expand. If the plunger seal swells it may not allow enough room for the plunger to move up and then still allow flow through the orifice. It’s important to make sure the media is compatible with both the plunger seal and O-ring material. Swelling is more critical in the plunger seal as swelling in an O-ring may not necessarily cause an external leak but could cause it to break down over time. Review how to calculate flow rate through a valve here to verify you have proper flow.

2-Way NC Valve Won’t Close:

As mentioned above, the spring force is pushing the plunger down and closing the valve. If the spring were to fail, then the valve won’t be able to close effectively. The inlet pressure will still push the plunger down when it is de-energized, but it can’t be relied on, especially for low pressures. The spring is a wetted component for all valves, except isolation valves. To learn more about what the difference is check out the difference between an Isolation Valve and a Direct Acting Valve here. Therefore, if the media is corrosive it can corrode the spring over time and cause it to break.

Another reason for a 2-Way NC valve may not close, is if debris or small particles are in the media. Even small amount of debris can be deposited on the orifice seat or plunger seal which will prohibit the formation of a proper seal. Mesh filters are recommended for media that may contain debris to keep them out of the valve. Also, with more viscous medias, it’s important for them to be flushed out routinely so they don’t harden within the guide tube assembly. This will then limit the movement of the plunger and may prevent it from moving down and sealing on the valve seat.

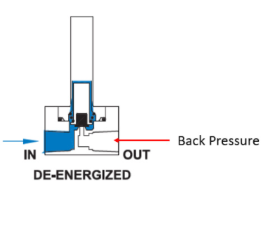

Another issue that may prevent a 2-Way NC valve from closing is if the under-seat pressure is too high. As mentioned above normal flow comes in through the inlet and is over-seat, which helps push the plunger down onto the seat. If there is too much pressure under-seat it can potentially push the plunger up and allow media to flow backwards. Review the max back pressure this can withstand per orifice size here.

Still focusing on the media, another potential failure mode is if the media can cause the plunger seal to swell and expand. This expansion and contraction overtime could cause the plunger seal to become brittle and deteriorate, and no longer provide any sealing. It’s important to make sure the media is compatible with both the plunger seal and O-ring material. Swelling is more critical in the plunger seal as swelling in an O-ring may not necessarily cause an external leak but could cause it to break down over time. It’s important to understand the difference between an elastomer seal and a non-elastomer seal so they can be specified correctly. Review the difference between them here.

In addition, we mentioned recommending mesh filters to help keep debris from entering the valve. However, debris may also form from the internal valve components rusting and/or corroding and depositing on the valve seat. This can cause an issue with the plunger seal making a proper seat and causing an internal leak. Media compatibility is crucial to the valve's performance. For more information on selecting the correct body and seal material click here.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER