When choosing a solenoid valve, selecting the seal material is an important step. Understanding the difference between an elastomer seal and non-elastomer seal is crucial to the valve performing correctly in your application.

An elastomer seal will have viscosity and elasticity which can be known as having viscoelasticity. In laments terms this means the seal is soft and can regain its shape and size after being compressed. This makes it a great material to ensure a liquid and airtight seal. Some of the elastomer seals available in Gems solenoid valves are Nitrile (Buna), EPR, FKM (Viton), Neoprene, Silicone, and Perfluoroelastomer (FFKM).

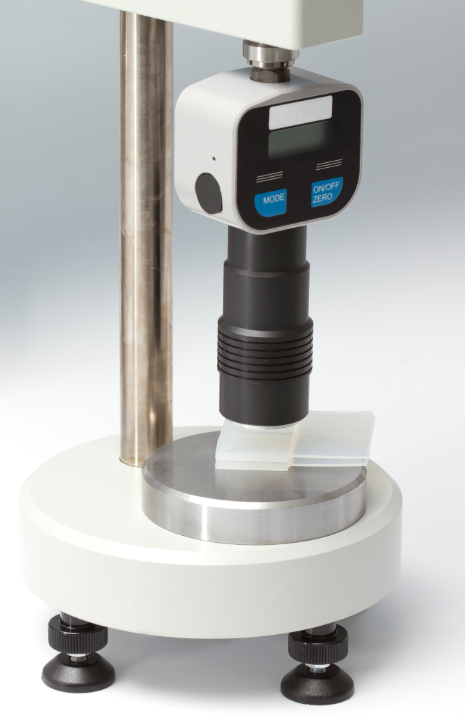

A non-elastomer seal will have less viscosity and elasticity then an elastomer seal. They are typically much harder and thus a higher durometer. An elastomer seal will have a lower durometer than a non-elastomer seal, which is typically measured using the Shore A scale. Some non-elastomer seals available in Gems solenoid valves are PTFE (Teflon) and Variseal, and Rulon.

So why choose a non-elastomer seal over an elastomer seal if the elastomer can seal better? You may consider a non-elastomer seal for a few reasons. If the media is corrosive a non-elastomer seal like PTFE is an excellent inert choice, compatible with many liquids. Also, when the media is extremely hot or cold, like in a cryogenic application, Rulon or PTFE can withstand those extreme temperatures. Elastomer seals may swell under hot temperatures and restrict the flow. In extreme low temperatures, elastomer seals may become brittle and fail.

Understanding the difference between elastomer and non-elastomer seals is key to selecting the right Gems Solenoid valve for your application.

Learn more about our Gems solenoid valves HERE

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER