Common Terms used with Gems Sensors Pressure Switches:

Proof Pressure:

- Proof pressure is the maximum pressure that can be applied to a pressure sensor without causing mechanical degradation (leaking) or shift in set point.

- For example, after experiencing a pressure spike above the rated proof pressure specification, a pressure switch may now trigger at 100 psi (7 bar) rather than the preset of 80 psi (5.5 bar).

Burst pressure:

- Burst pressure is literally the amount of pressure that will cause a pressure switch to physically fail.

- This can lead to a leaking diaphragm or a piece of the housing becoming loose.

Pressure Port:

- The pressure port is the threaded part of the sensor that will connect the pressure switch to the customer’s fluidic system:

- The sizes and styles range from tapered styles (NPT) to straight thread styles (SAE and Metric).

Wetted parts:

- This is the area of the sensor that gets exposed to the customer’s media or fluid.

- This can include the pressure port, the diaphragm, and the O-ring on the port.

- It is very important to ensure that you match your media/fluid with the correct wetted parts to ensure a long-lasting application.

- Standard and optional wetted parts for each individual pressure switch series are listed on their data sheet.

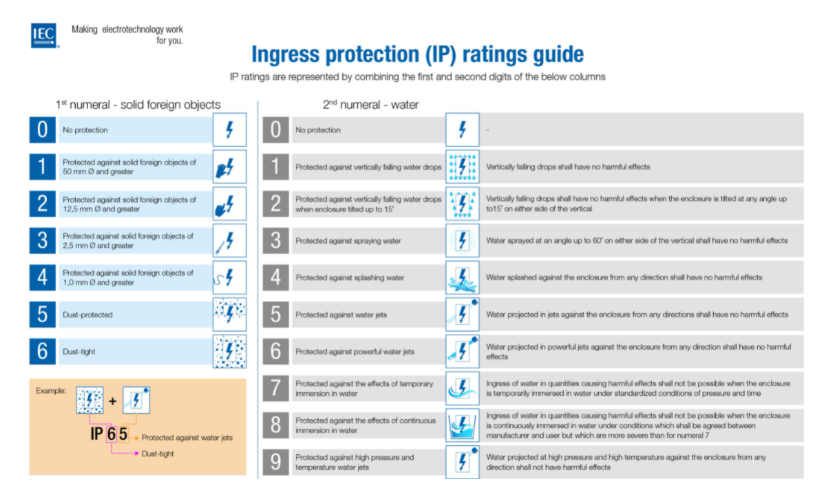

IP ratings:

- IP stands for Ingress Protection.

- This is a rating determining how well a device is resistant to either or water or dust.

- Gems follows the IEC Standard 60529 as well as the DIN standard DIN 40050-9.

The IEC Standard is broken down to specify the level of protection:

- First Numeral – Solid Objects Ingress

- Second Numeral – Water Ingress

- BLOG on how the PS61 Series pressure switches are IP rated

Circuit:

Pressure switches are available in three configurations:

SPST/NO:

- Single-pole, single throw / Normally Open

- A two wire or two terminal electrical switching element that does not allow current to flow until pressure is applied to close the circuit.

SPST/NC:

- Single-pole, single throw / Normally Closed

- A two wire or two terminal electrical switching element that allows current to flow until pressure is applied to open the circuit.

SPDT:

- Single-pole, double throw

- A three wire or three terminal electrical switching element that has one normally open (NO) and one normally closed (NC) circuit with no pressure applied. It can be wired as either an NC circuit, NO circuit or both.

Note: for pressure switches, the normal state (as in Normally Open) is when there is no pressure on the pressure port.

Contacts:

- A pressure switch is typically electrically connected to a PLC (Programmable Logic Controller) or pump or light to signal that the pressure inside the customer’s system has moved past the pre-determined pressure level set point.

- Contacts refers to the internal electrical connections that create the make or break circuit when a pressure switch is open (active) or closed (inactive), much like the light switch on the wall in your home.

- Care must be taken to ensure that not too much voltage or current travels thru the internal contact inside the pressure switch. Each pressure switch’s data sheet has a maximum electrical rating.

- BLOG on how to determine if you need the standard Silver or the optional Gold contacts.

Repeatability:

- The limit of deviation from the desired setpoint under a given set of environmental and operational conditions.

Deadband:

- The arithmetic difference in pressure between the rising pressure (or vacuum) setpoints and the falling pressure (or vacuum) setpoints.

- All electromechanical pressure switches exhibit a deadband.

- Minimum and/or maximum deadbands are often specified so that a pressure switch can be used as a cost effective control method in pneumatic and hydraulic systems.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER