Will different liquid media affect the time delay for optic sensors?

If the viscosity is similar, the time delay should be the same for different media.

What is the difference between "sinking" and "sourcing?"

Sinking and sourcing are terms used to describe how an associated load (the device being turned on or off by the sensor) is powered in relation to the sensor. Sinking, the more widely used of the two, involves the switching of load current (power) supplied by a power source external to the sensor. In a sinking configuration, current passes through the load first, through the output switch of the sensor second and lastly to ground. A sensor with a sinking output switches the ground, or negative, leg of the circuit. In contrast, sourcing refers to a configuration in which the sensor is the source of the current required to power the load. In a sourcing situation, current supplied by the sensor passes through the load second and then to ground. A sensor with a sourcing output switches the positive leg of the circuit.

Can you connect more than one 12 volt Sinking Electro Optic Sensor to the Opto Pak Controller?

The Opto-Pak controller was designed for just one relay output. However, when using 12 VDC Electro Optics in parallel with one Opto-Pak controller Part# 149536 or 149535 with Nema4X Enclosure, the following is possible:

Maximum capability: 100Ma

Maximum optic sensors: 4

For multiple sensors wired in parallel to one Opto pak Controller, the sensors will exhibit logical OR operation:

Dry Sink sensors: if any sensor is dry, the Opto Pak Controller relay will be energized, and all sensors would have to be wet to de-energize the relay.

Wet Sink sensors: if any sensor is wet, the Opto Pak Controller relay will be energized, and all sensors would have to be dry to de-energize the relay.

Does Gems offer an optic sensor with a time delay?

For large volume OEM applications, a custom time delay is available on the programmable microprocessor version of the ELS-1150, which can be programmed for on, off or both delays from 2 seconds to 255 seconds. All delays have a ±1 second tolerance. Call Gems for more information.

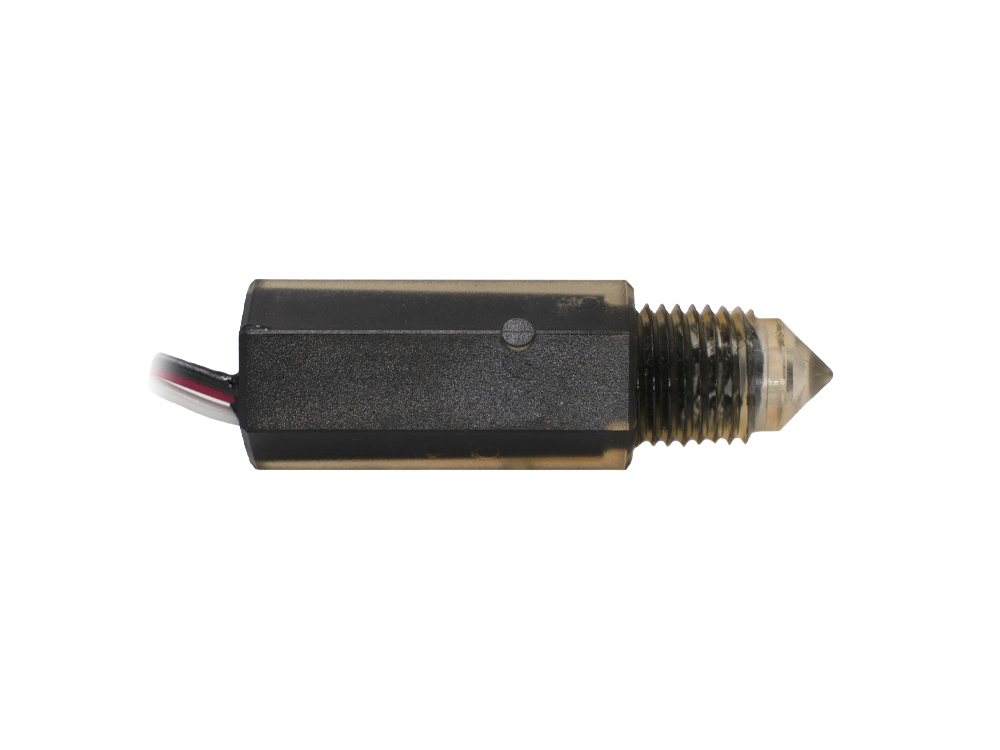

Is there a preferred mounting position for the ELS-1150 and ELS-1150XP Optical sensor?

These sensors must be mounted horizontally or up to 45 degrees from horizontal only. Reason, possible drips on tip can cause false indication. Also do not want to create air pockets.

What is the diode part number that is referenced for inductive loads per the wiring diagram for an Optic sensor?

Reference Diode part# 1N4004, (400V peak input voltage)

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER