CAP-300 Capacitive Level Sensor

PRODUCT DESCRIPTION:

CAP-300 Series Capacitive Level Sensor is compact, low-maintenance and highly-durable sensor that tolerates coating, can be mounted in any position and is compatible with coolants making it the ideal OEM solution for power generation equipment, off-highway

vehicles and generators, as well as food & beverage, medical, rail and HVAC applications. NSF/ANSI 169 compliant models are available for use with water, coffee and dairy.

- Durable sealed design - IP67

- Developed for the most rugged aqueous applications

- Tolerates coolant coating

- Small size - 2˝ (51 mm) long

- Now available in 316L S/S for Food & Beverage Applications

FEATURED DOWNLOADS:

Features

- Durable sealed design - IP67

- Developed for the most rugged aqueous applications

- Tolerates coolant coating

- Small size - 2˝ (51 mm) long

- Now available in 316L S/S for Food & Beverage Applications

- Agricultural Equipment

- Alt Energy Equipment

- Food & Bev Equipment

- Food & Beverage - Beverage dispensing

- Food & Beverage - Dairy

- Food & Beverage - Food Service Equipment

- Food & Beverage - Other

- Food & Beverage - Ovens

- Food & Beverage - Specialty dispensing

- General Industry

- General Industry - Appliance

- General Industry - Car Wash Equipment

- General Industry - Cleaning Equipment

- General Industry - Compressors

- General Industry - Laser Equipment

- General Industry - Motors

- General Industry - Other

- General Industry - Printing Equipment

- General Industry - Skid Manufacturer

- HVAC/R - Air Conditioning Systems

- HVAC/R - Chillers

- HVAC/R - Cooling

- HVAC/R - Critical Care

- HVAC/R - General HVAC

- HVAC/R - Humidifers

- HVAC/R - Other

- HVAC/R - Refrigeration

- HVAC/R Equipment

- Marine - Commercial - Aftermarket

- Marine - Commercial - Container Ships

- Marine - Commercial - Cruise Ships

- Marine - Commercial - Other

- Marine - Commercial - Pleasure Craft

- Marine - Commercial - Repair Yard

- Marine - Commercial - Ship Owner

- Marine - Commercial - Ship Systems

- Marine - Commercial - Shipbuilder

- Marine - Commercial - Workboats

- Marine - Commercial - Yachts

- Marine - Govt & Military - Homeland Security

- Marine - Govt & Military - Marine

- Marine - Govt & Military - Marine - Other

- Marine - Govt & Military - Military

- Marine - Govt & Military - US Government

- Marine Vessels

- Medical - Analytical Instruments

- Medical - Imaging

- Medical - Lab

- Medical - Laboratory & Testing

- Medical - Life Sciences

- Medical - Medical Lasers

- Medical - Other

- Medical - Radiology

- Medical Equipment

- Off Highway Vehicles

- OHV - Agricultural Equipment

- OHV - Construction Equipment

- OHV - Fertilizer

- OHV - Forestry Equipment

- OHV - Highway Construction Equipment

- OHV - Industrial Equipment

- OHV - Lawn Equipment

- OHV - Material Handling

- OHV - Military Vehicles

- OHV - Mining Equipment

- OHV - Other

- OHV - Recreational Vehicles

- OHV - Refueling Trucks

- OHV - Specialty Equipment

- OHV - Street Sweepers

- Power Gen Equipment

- Power Generation - AC General

- Power Generation - AC Lift

- Power Generation - AC/DC

- Power Generation - Distributed Generation

- Power Generation - Fuel Cell

- Power Generation - Generators

- Power Generation - Green Energy

- Power Generation - Other

- Power Generation - Power Generating Facilities

- Power Generation - Power Transmission Companies

- Power Generation - Solar

- Power Generation - Switchgear

- Printers

- Specialty Vehicles

- Transportation

- Transportation - Buses

- Transportation - Commercial On-Road Vehicles

- Transportation - Fire Trucks

- Transportation - Other

- Transportation - Rail - Locomotive

- Transportation - Rail - Other

- Transportation - Rail - Passenger

- Transportation - Specialty Vehicles

The CAP-300 is useable from 100% water to 100% coolant or any mixture of coolant and water.

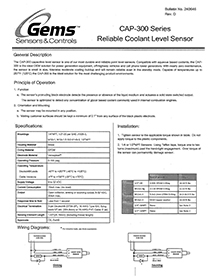

What is the function of the CAP-300?It is a point level sensor for applications such as power generation equipment, off highway vehicles and cell phone tower generators. The sensor’s protruding black electrode detects the presence or absence of the liquid medium which is composed of 0-100% mixture of Glycol based coolant and water, and actuates a solid state switched output.

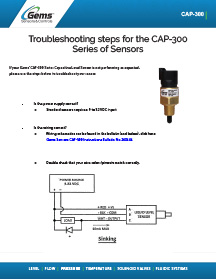

What is the signal output logic for the CAP-300?Open collector, Sinking NPN or Sourcing PNP output, 9-32 VDC, 30mA max.

What electrical terminations are commonly offered for the CAP-300?3 pin Deutsch, 18 AWG type SXL flying leads or 18 AWG PVC cable.

Does the CAP-300 have circuit protection?Reverse voltage: up to 45VDC; Overvoltage 80VDC min. Meets requirements of ISO 7637-2. Output protected against shorts to ground or supply.

If the composition of the coolant changes overtime, will the CAP-300 have to be recalibrated?Recalibration will not be necessary if the coolant changes, the sensor will continue to operate.

Will the CAP-300 require maintenance?Nearly zero maintenance, the sensor is small in size, tolerates coating and will remain reliable even in the standby mode.

What is the default dielectric constant for the CAP-300?The sensor switching threshold is factory set at a Dielectric Constant (Dk) value of 30. Media with a Dk greater than 30 will be detected as “WET”. Conversely, media with a Dk less than 30 will be detected as “DRY”.

Will the CAP-300 work for an oil application?The current design is specifically for conductive coolant applications. The dielectric of oil is too low and will not work with the current design.

What is the best orientation and mounting for the CAP-300?The sensor is functional in any orientation. Mating customer surfaces shall be kept a minimum of 0.1" from any surface of the black plastic electrode. Gems recommends that the black sensing tip is not recessed into the side of a tank or adapter fitting because liquid (or air) may become trapped leading to false signals. Consult the factory for advice in this situation.

What is the delay time for the CAP-300?Standard units come with no delay. The response time is less than one second. For low quantities, we can offer a 5 and 10 second delay. Tolerance +/- ½ second. Gems can also customize the delay up to 99 seconds for large volume OEM applications. Call Gems for more information. Delays are useful when the liquid being sensed is subjected to frequent sloshing or the reservoir’s attitude changes significantly.

Should I be concerned with moisture intrusion with the CAP-300?It is a sealed design which prevents fluid intrusion.

Will density, opacity and viscosity variation as well as the accumulation of debris and chemicals found in the common coolants impair the sensor’s ability to detect the presence or absence of the medium?It is not likely that this will affect the sensor.

What is the Mean Time Between Failure rate for the Cap-300?MTBF: 146,426.61 hours for ground mobile applications which are more severe.

What is the failure rate for the Cap-300?Failure Rate: 6.820 PPM Hrs.

What is the diode part number that is referenced for inductive loads per the wiring diagram for a Cap-300?Reference Diode part# 1N4004, (400V peak input voltage)

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER