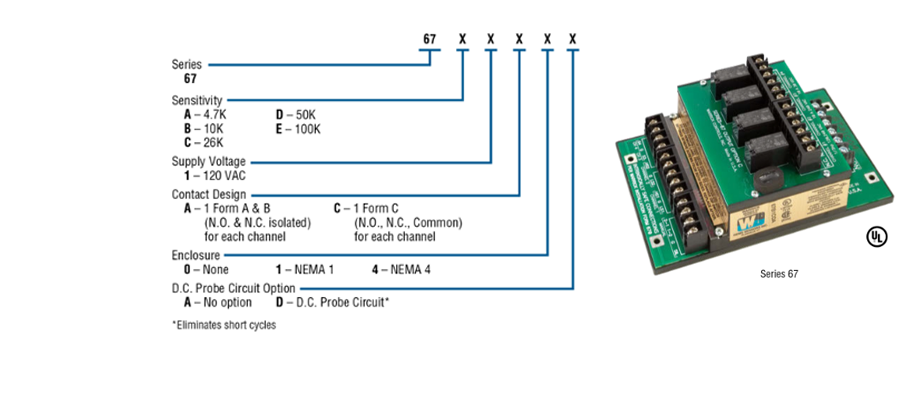

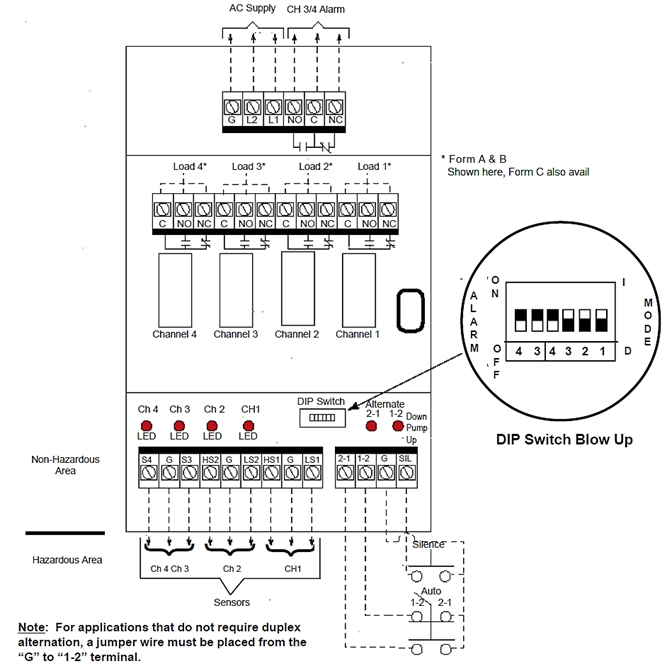

The 67 Series multi-function/duplex pump system control module is a complete 4 channel level control solution for use with float-type (dry contact) or conductive level sensors. Designed for simplex or duplex pump/solenoid vale control with high and low level alarms. It is designed for applications where intrinsically safe control in hazardous locations may be required, but also works for non-hazardous applications.

Sensitivity

The general rule is the sensitivity of the control (e.g. 10K, 26K etc.) should be greater than the resistance of the liquid. The less conductive (more resistance) a liquid is, the more sensitive the control module needs to be. It is usually better to choose the sensitivity level that is above, yet as close to the conductivity/resistance as you can. Choosing a level too high could sense mist, foam, steam, etc., or even cause the module to not operate properly. Gems has offered a conductivity chart HERE. Please note, if your liquid conductivity is too high for any sensitivity level listed, then you will need to consider a float-type level sensor.

Supply Voltage

The supply voltage selection is what is used to power the control module.

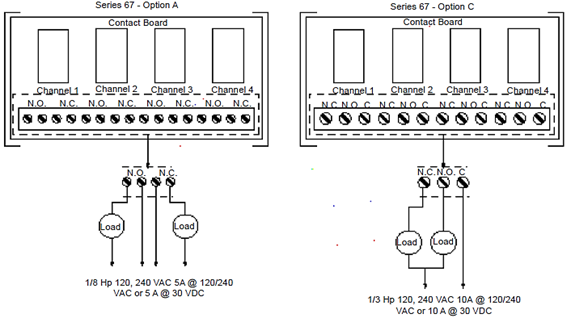

The 67 series offers two different load contact types. Form A & B consists of one normally open (N.O.) and one normally closed (N.C.) contact each electrically isolated and paired with their own independent commons. Form C consists of one N.O. contact and one N.C. contact that share a common terminal. When one contact is open the other is automatically closed.

Enclosure

You can choose to have the control module affixed within a 6x6x4 fiberglass NEMA rated enclosure.

Type 1 enclosure constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt).

Type 4 offered is type 4X enclosure constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (windblown dust); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (rain, sleet, snow, splashing water, and hose directed water); that provides an additional level of protection against corrosion; and that will be undamaged by the external formation of ice on the enclosure.

D.C. Probe Circuit Option

Probe circuit option gives you the choice of using AC or DC voltage for the sensing probe signal received by the control board. DC Probe Circuit option eliminates the possibility of “short cycling”. The short cycle refers to the control board relay changing states or “cycling” prematurely. An AC sensing circuit comes in the form of a sine wave. It changes direction from positive to negative voltage crossing zero. When the control circuit board detects the input signal as the wave is crossing at or near the zero, it can see that as a no-signal detection and change the state of the relay. DC signal is one-way direct without a sine wave. It does not change direction and is either always positive or always negative. The control board cannot see a false signal in this case. So, why even have the AC option? Using DC can cause polarization of the electrodes and electrolyte which leads to error in measured conductance values over a period of time. Also, water is an insulator with dielectric properties. The higher the purity of water (less contaminants) results in lower current flow. AC signal sensing is better suited for these applications.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER