The series 16M liquid level controller is enclosed in a clear Lexan modular design with a plug-in socket for use with float-type or conductive probe-type level sensors. It can be configured for single level indication (e.g. high alarm), or for pump up or pump down differential service. When configuring a Warrick 26M you will need to select from several options which will be explained in this blog.

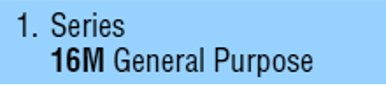

Mode of Operation

“Mode of Operation” covers two important parts of your configuration. The first thing to consider is whether your control will be direct acting or inverse acting.

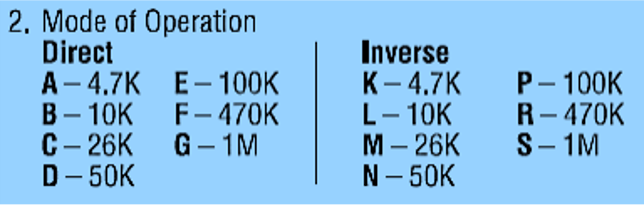

Single level service

Direct Acting Inverse Acting

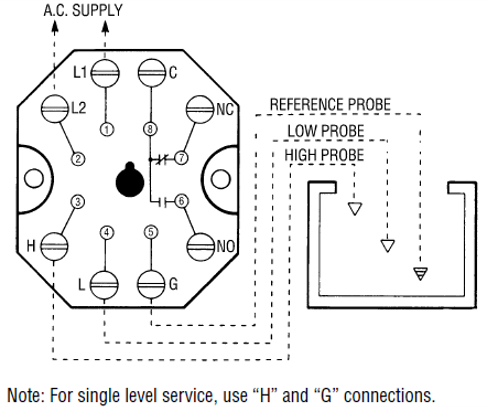

Direct acting refers to the state of the normally open (NO) contacts in relation to rising liquid level. The contacts remain open while liquid is below the high-level probe connected to the (H) terminal on the 16M series control socket. These NO contacts then remain closed while liquid is in contact with the high-level probe.

Inverse acting refers to the state of the normally open (NO) contacts in relation to rising liquid level. The contacts remain closed while liquid is below the high-level probe connected to the (H) terminal on the 16M series control socket. These NO contacts then remain open while liquid is in contact with the high-level probe.

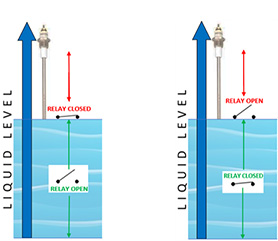

Differential level service

Direct Acting Inverse Acting

Direct acting, commonly called “pump down” or “drain” refers to the state of the normally open (NO) contacts in relation to the liquid level between the high and low probe ends. When liquid reaches the high-level probe connected to the (H) terminal on the DC series control socket the contacts close. They remain closed until liquid level falls below the low-level probe connected to the (L) terminal on the 16 series control board. Once it falls below the low-level probe the NO contacts open and remain so until reaching high-level probe, repeating the process.

Inverse acting, commonly called “pump up” or “fill” refers to the state of the normally open (NO) contacts in relation to the liquid level between the low and high probe ends. When liquid falls below the low-level probe connected to the (L) terminal on the DC series control socket the contacts close. They remain closed until liquid level rises to contact the high-level probe connected to the (H) terminal on the 16 series control board. Once it reaches the high-level probe the NO contacts open and remain so until falling below the low-level probe, repeating the process.

Once you have decided on direct or inverse, your next consideration is how sensitive does the control module need to be? The general rule is the sensitivity of the control (e.g. 10K, 26K etc.) should be greater than the resistance of the liquid. The less conductive (more resistance) a liquid is, the more sensitive the control module needs to be. It is usually better to choose the sensitivity level that is above, yet as close to the conductivity/resistance as you can. Choosing a level too high could sense mist, foam, steam, etc., or even cause the module to not operate properly. Gems has offered a conductivity chart HERE. In some applications the wire distance from probe to control module needs to be factored in, and that guide is found HERE. Please note, if your liquid conductivity is too high for any sensitivity level listed, then you will need to consider a float-type level sensor.

Supply Voltage

The supply voltage selection is what is used to power the control module (attached to terminals L1 and L2).

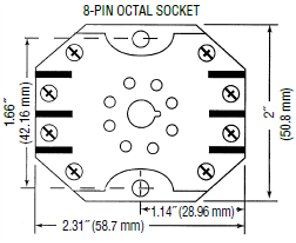

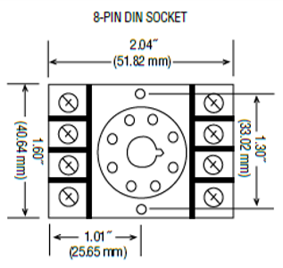

Socket Style

Plug-in style sockets allow for easy install and removal. After you have your socket mounted to your panel with all wires attached, future orders can be “M”, module only, without the need for re-wiring.

Enclosure

You can choose to have the control module affixed within a 6x6x4 fiberglass NEMA rated enclosure.

Type 1 enclosure constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt).

Type 4 offered is type 4X enclosure constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (windblown dust); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (rain, sleet, snow, splashing water, and hose directed water); that provides an additional level of protection against corrosion; and that will be undamaged by the external formation of ice on the enclosure.

Time Delay

The time delay option can be used to prevent excessive relay operation due to waves, turbulence, disruptions in the water level when at or near the probe end. With time delay on increasing level, the liquid must be in contact with the high electrode for the full duration of the time delay before control will operate. With delay on decreasing level, the liquid must be below the low electrode for the full duration of the time delay before control will operate. In single level service, terminals 3 and 4 must be jumpered together to achieve time delays on both increasing and decreasing levels or just decreasing level

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER