ULS-200 vs. Traditional Electro-Optic Sensors: Superior Performance in Liquid Detection

06.06.24

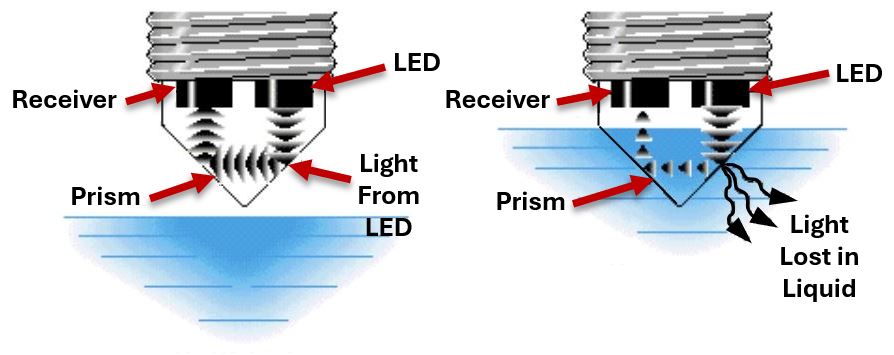

Discover why the ULS-200 sensor outperforms traditional electro-optic sensors in liquid detection. Ideal for high viscosity, high-pressure, and humid environments, it offers unmatched reliability.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER

.png?sfvrsn=7a1634_1)