If your Gems CAP-300 Series Capacitive Level Sensor is not performing as expected, please use the steps below to troubleshoot your sensor.

- Is the power supply correct? Standard sensors require a 9 to 32 VDC input.

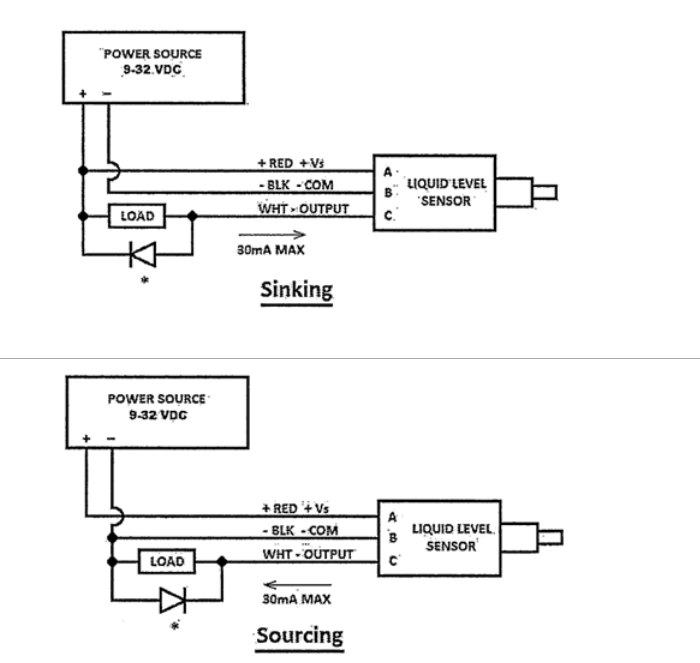

- Is the wiring correct? Wiring schematics can be found in the bulletin (and below), click here

Double check that your wire colors/pinouts match correctly.

Orientation and mounting:

- The CAP-300 is designed to work in any orientation

- The black plastic tips should be kept at least 0.1” (2.5mm) away from any surface

- Is the CAP-300 probe tip fully exposed to the media, and not installed in a port or tube where media can get trapped?

Cleanliness:

- Is the port/tip clean?

- Any dried-on debris that could cause a false reading?

Liquid/Media:

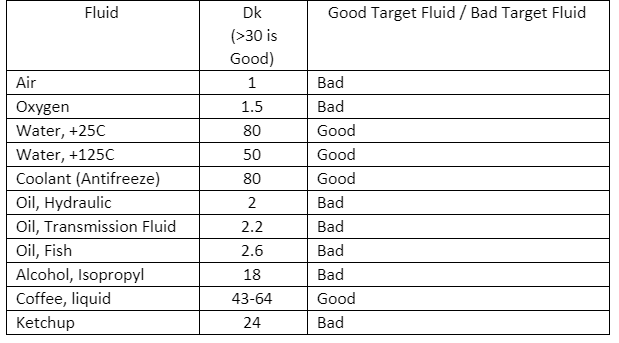

- The CAP-300 relies on the Dielectric Constant (Dk) of your fluid in order to detect the difference between fluid present and no fluid present.

- The sensor switching threshold is factory set at a value of 30.

- Media with a Dk greater than 30 will be detected as “WET”. Conversely, media with a Dk less than 30 will be detected as “DRY”.

Some common Dk values:

Are you trying to detect foam? The CAP-300 was designed to ignore foam and will not detect it as wet.

Best Practices for Troubleshooting:

- Test with room temp tap water.

- This way, it is a good known target fluid.

- Remove the sensor completely from your mechanical and electrical system.

- This will isolate any variable in the circuitry.

- Use a known good power supply as well as a known good voltmeter and see if the sensor responds to water.

If these steps do not yield favorable results, please contact Gems via: Technical Support

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER