Gems Sensors manufactures flow switches, and typically they are calibrated and set with room temperature water. However, when using different liquids with different viscosities will that effect the accuracy of the setpoint? The short answer is yes, changes in viscosity will affect the setpoint of the flow switch.

First let’s discuss more about viscosity and what viscosity means. Viscosity in general terms is a measure of the fluid’s resistance to flow. The greater the viscosity, the greater the fluid’s resistance to flow. For example, we’ve all heard the term “you’re as slow as molasses.” That term is referring to how slow molasses will flow, because it is very viscous (has a high viscosity). Molasses has a viscosity of approximately 5,000-10,000 centipoises (unit of measurement for viscosity), where water is approximately 1.

So how does an increase in viscosity affect the setpoint on Gems flow switches? The rule of thumb is that as viscosity increases (thicker liquid), the setpoint will decrease. Let’s think about why this happens. A thicker more viscous liquid won’t flow as freely as a less viscous, thinner liquid. As this thicker liquid is moving through the flow switch it will be held together more and may stick to the inner walls and inner flow switch components. This will make it harder for the piston/shuttle to return to its resting position (no flow), and therefore easier to actuate (indicate flow). Since it is easier for the flow switch to actuate with this more viscous liquid, less flow rate is required, which essentially lowers the setpoint.

For example, a setpoint of 1.5 GPM that is calibrated with room temperature water, may only require a flow rate of 1.0 GPM with a more viscous liquid like motor oil. The opposite reaction will then happen for liquids that are less viscous than water. Since the liquid will be thinner it will be able to flow more freely than water, which will then require a higher flow rate to actuate the switch. Therefore, when using a liquid with a lower viscosity then water, the setpoint will increase.

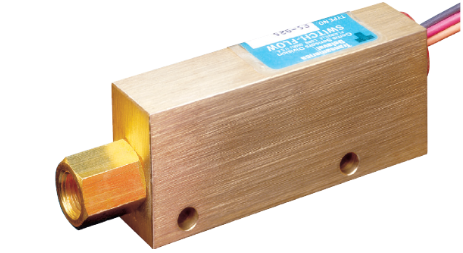

Gems FS-930 Oil Flow Switch will compensate for changes in viscosity if the viscosities range from 40 to 2000 SSU. This is ideal for use in applications where liquids of different viscosities are blended, or for use in lubrication systems where oil flow monitoring is crucial at startups.

Flow Products Cheat-Sheet Question about Gems Flow switches?

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER