Semiconductor manufacturing involves the process of producing semiconductor devices like metal-oxide semiconductors (MOS) which are components used in the integrated circuit (IC) chips. These semiconductor chips are used in computer processors, micro controllers, and memory chips like flash drives.

Cooling and temperature control systems are critical throughout the semiconductor manufacturing process. The cooling systems are usually liquid-liquid and have benefits over liquid-air cooling because they don’t require a fan, and the heat can be rejected into the facility cooling water which doesn’t add heat to the conditioned air.

During the semiconductor manufacturing process heat is generated inside the machines, and this excessive heat can lead to poor yield. To pull the heat out of the process a coolant loop around the electrical equipment containing either a glycol-based coolant or even an oil-based coolant. Monitoring this coolant is crucial as it requires constant flow to effectively pull the heat out of the machine and transfer it elsewhere.

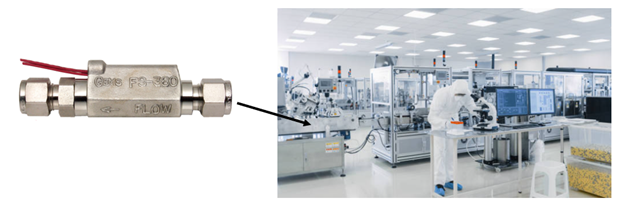

Challenge: Finding a reliable flow switch that can detect low flow rates and have a low pressure drop.

Coolant liquid is critical in many applications, including semiconductor manufacturing. This equipment is expected to have a very high uptime and perform with high reliability. Having a piece of semiconductor manufacturing equipment breakdown during use is frustrating to the operator and even more frustrating to lose semiconductor chips! Uptime is the most critical characteristic that the solution must exhibit.

Solution: Gems Sensor’s FS-380 Flow Switch

The FS-380 is an inline design flow switch which reduces high pressure drops. This is crucial for coolant liquid as the flow rate needs to be consistent and at a substantial rate to pull the heat away from the sensitive electronics within the semi-con equipment. The piston-based design of the FS-380 flow switch is a simple yet reliable design with excellent repeatability. This piston and reed switch design is not affected from nearby equipment causing voltage noise and other issues that may affect more sensitive electronic based sensors.

Additional Benefits of the FS-380 Flow Sensor:

- With setpoints as low as 0.15 gallons per minute it can detect very low flow rates and still sense loss of flow

- With either a 316 stainless-steel or Brass body, it is a rugged flow switch

- Available in multiple different port sizes and types including 1/2", 3/8” NPT, 1/4", 3/8” Compression, and 1/2" Barb.

- Operating temperature range of -20°F to +275°F it can withstand extreme media conditions.

Full FS-380 Flow Switch details can be found here

Adjacent products:

- PS11: low pressure switch

- CAP-300: coolant levels, solid state

- XLS-1: fluid reservoir levels, solid state

- LS-3: fluid reservoir levels, from the top

- LS-7: fluid reservoir levels, from the side

- LS-350: multi-point level with siphon tube

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER