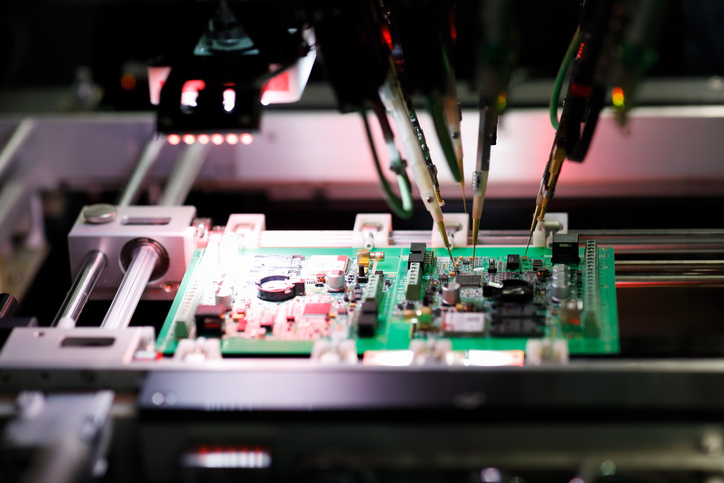

Demand continuously increases in the SEMICON industry to manufacture Integrated Circuit (IC) chips and Printed Circuit (PC) boards in much higher quantity to satisfy the needs in the industry. The global demand for electronics in the Communications, Computer, Automotive and Industrial markets has not slowed down.

In these markets, the chips and boards are also being pushed to run at faster speeds (to handle more processes and functions) as well shrink down their sizes to be used in smaller packages.

- As manufacturing throughput increases, the processes involved become hotter due to more energy consumed and smaller spaces being utilized.

- As the chips’ speed is increased, they consume more energy which in turn creates heat.

To keep these two heat characteristics in control, manufactures test the chips and boards at very high speeds. With this high speed, heat is created, and the extra heat can damage the electronics. To combat this, manufactures turn to testing systems that use cooling loops to keep the tests in check. Monitoring these coolants loops for constant pressure is crucial in order to keep the process’s temperatures under control and to not damage the chips and boards under test.

Challenge: Finding a pressure sensor that can provide an accurate signal even during demanding high temperature conditions, survive a high number of cycles as well as be airtight to prevent leaks.

To keep up with demand, these testing systems run constantly. Exposing the sections of the system to high temperatures and a high number of operational cycles with very little room for error or downtime. The pressure sensor used needs to be able to constantly give the correct signal output whether it is on the 10th cycle or the 100,000th cycle. Leaking is also big issue with low-cost suppliers. To keep manufacturing costs down, they utilize an internal O-ring that can break down over time and leak. Again, with no downtime for the test equipment, this type of failure is not tolerated.

Solution: 3100 Series Pressure Sensors

The new 3100 Series Pressure Sensors use no internal O-rings in the chamber that holds the media (coolant, oil, air, etc.). The stainless-steel pressure ports and sensing diaphragms are laser-welded together to make an air-tight leak-proof seal. This will prevent leaks today as well as years in the future as O-rings can break down being exposed to harsh cleaning chemicals as well as over time and cause leaks. Able to operate up to +125C and along with the 100 million cycle lifetime, the 3100 Series Pressure Sensors are a perfect fit to provide a continuous feedback of coolant pressure for your SEMICON testing system.

Adding the 3100 Series Pressure Sensors to your SEMICON testing applications is a large asset to ensure your equipment will have a long life and low maintenance requirement.

Features of the Gems 3100 Series Pressure Sensors:

- Exceptional Long-Term Stability = No need for costly field calibration or replacement

- Thermally compensated = Consistent performance under wide temperature conditions

- Stainless Steel body = Able to with stand harsh chemicals and gasses

- Sealed to IP67 = heavy water spray, power-washing

- Enhanced RFI, EMI, and ESD Protection = Clear uninterrupted signal in harsh electrical environments

- Computer Controlled Calibration = High 1:1 Interchangeability from unit to unit

- Passes 20G Vibration test and IEC Free Fall test = Rugged design to handle excessive shock and vibration conditions

Industries:

- Semiconductor

- Power Generation

- Specialty & Off-Highway Vehicles

- Transportation

- Alternative Energy

- Marine

Adjacent Products:

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER